BAFFLE STACK FROM THE CCF/Swiss Impuls II-A

Effective Dec 15, 1999

The Impuls II-A Suppressor is $750.00 with the exception of the Impuls II-A

for the MK-23

The CCF / Swiss Inc. line uses only CNC machined components, including baffles. Each baffle is machined to such a high tolerance it will require a slight spray of silicone oil to insert but will slide home like a piston in an engine block.

The CCF/Swiss baffle employs interlocking steps machined integral to the baffle to self-space & to self-align a baffle with those immediately in front and behind. No spline alignment tool is necessary to assemble this suppressor. The design goal from the outset was to develop a baffle that would not suffer the short life expectancy of stamped baffles. Since machined baffles can be constructed far thicker and from more durable material (Inconel or 4140 steel for the first two baffles that are exposed to the blast from powder residue exiting the barrel).

BENEFITS OF CNC MACHINED BAFFLES

CNC machined baffles allow ease of assembly / dis-assembly without alignment tools. Additionally, because of the high tolerance consistency achievable with CNC, caliber conversions can be accomplished on most of our models in minutes.*

*Unfortunately, ATF regulations require a $200 tax stamp on any baffle transferred individually. However, at a later date, a customer can transfer the unit back to us on a Form 5 repair / modification transfer for a caliber conversion without incurring a second $200 transfer tax.

Most suppressors are sealed due to the fact that the baffles are stamped from stainless steel (sheet stock), usually .090" wall thickness. Stampings, because of dimensional tolerance control problems, are usually made smaller in their outside diameter than the inside diameter of the suppressor tube body. This allows for adjustment & alignment of the baffles vertically / horizontally to allow the bullet pass-through holes to be aligned at assembly. Assembly requires a spline alignment shaft tool to hold the baffles in alignment while the compression lock ring is tightened. Basically, compression (friction) is holding those baffles in alignment.

The problem is that those stampings are exposed to an extremely high temperature environment. While in that heated state, the baffles are exposed to extremely high pulse pressure from the expansion gases every time the weapon is fired. Depending on the quality of the steel they have been stamped from, stamped baffles will last anywhere from 500 to 3000 rounds before they have stretched and deformed to the point that they become loose.

Those baffles might have first seen

life in the suppressor with a thickness of .090", but 500 rounds later

have now stretched to the point that they are possibly .089888". With

anywhere from 12 to 20 baffles in the suppressor, that loss of thickness due

to stretch is enough to allow the baffles to become loose and move laterally

& vertically. We have a .45 caliber suppressor here from one of the industry's

hobby manufacturers that has a total of 400 rounds through it that sounds

like a bean bag chair when you shake it. Partially because the baffles are

loose and partially because, now that they are loose and moved laterally,

they are shaving copper off the bullets' jackets passing through the unit.

The manufacturer states that the unit is not to be disassembled by the user

but only to be returned for repair.

Customers are, for all practical purposes, forced to return their suppressor to the original manufacturer because none of the baffle openings are truly round (looseness has caused them to shave bullets, causing the bullet passage opening in the baffles to elongate). Guessing at the average diameter of the spline tool to machine for re-alignment is cumbersome and a compromise at best.

Another disadvantage of stamped baffles is that they are thin walled and are not the optimum choice for durability in the area of abrasion resistance to the "sandblasting" effect by powder residue as it exits the barrel. All the baffles in our suppressors are made of ordnance grade and because of the freedom offered by CNC machining, can be made in thicknesses specific to a caliber, i.e., rifle calibers can machined with a thickness approaching .50" in the body proper to better tolerate the sandblasting punishment they will be exposed to. That same "hobby" manufacturer's suppressor referenced earlier; the first two baffles look like they are about to be sandblasted to destruction with possibly another 200 rounds of life expectancy maximum remaining. Being generous and giving that hobby suppressor a 750 round life expectancy still makes a $550 suppressor look expensive compared to a 30,000 to 40,000** (see footnote below) round life on a $850.00 suppressor properly built in the first place, not to mention the assurance of not suffering any destructive effects on your pistol! If you have a buddy with a suppressor that utilizes stamped baffles, take a look at the first two baffles with a bore light.

The USP* IMPULS II-A suppressor concept was developed to meet the needs of police and military forces requiring a suppressed handgun that functions as reliably suppressed as it did unsuppressed. The B&T USP* IMPULS II-A Recoil Improvement System is designed for use on pistols employing the Browning lock-up system. With the recoil booster tuned & timed specifically for the individual model pistol's slide mass and cyclic rate, parameters which are critical if the pistol's life expectancy is to remain unaffected. Additionally, the bullet's impact point can be adjusted by a setting on the rear of the recoil booster. Using a wet charge such as water or other liquid coolant, the sound reduction can be improved by an additional 10 db. The USP* IMPULS II-A is intended for mounting on an extended and threaded barrel which can be supplied by CCF / Swiss Inc.

| Calibers: | 9MM, 40 S&W, 10MM & 45 ACP |

| Models: | HK USP series,

Glock 17, 19, 20, 21, 26, 27, 29, 30 SIG 226, 228, 229 & SIG Pro, other models on request |

| Specifications: | Weight: 294g

/ 10.35 ozs Length: 199 mm / 7.83" Diameter: 35 mm / 1.38" Suppression: 26+ db dry / 36+ db wet |

** I currently have 26,700 + rounds on the first suppressor that came off our production line - only reason I know is I've saved the carton flaps off the ammo cases (2/15/02)

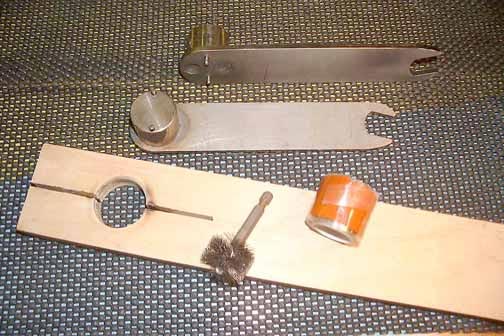

CCF IMPULS IIA Maintenance Tool Set

CCF IMPULS IIA Repair / Maintenance

Kit contains a spanner wrench,

a 30mm wire brush, a plywood clamping tool and a roll of

self-fusing silicone tape..................$55.00